-

Posts

4269 -

Joined

Content Type

Profiles

Forums

Store

Blogs

Events

Downloads

Supra Articles

Gallery

Everything posted by paul mac

-

i wouldn't be to worried about the water Jay, i probably have some of the biggest vents in supra world , the car has run fine for nearly 4 years and i do drown it when washing, besides if you cut the vents out you will make it even lighter

-

the cockpit pics are cool and really bring it home how exposed the guys flying these are, i read a book years ago about a US helicopter pilot in Vietnam flying Huey's called "Chickenhawk", on one mission he kept hearing this strange tick tick noise when coming into a hot LZ, after several tick ticks he realised what was causing it when he noticed the 7.62mm holes in the plexiglass BTW guys the blades reversing or slowing down on the clip is down to the camera shutter speed running at the same speed as the rotors, its like a strobe effect

-

if my supra is anything to go by it may be sat around for a long long time mate, nice toy

-

reserving judgement until their on but loving the fact your not afraid to try new things, if we all followed the herd life would be pretty dull

-

the front "crash bar" is not a life saving device you only have to look at its light weight aluminium construction to realise this, it is designed for low speed bumps to crumple and protect the chassis legs and surrounding bits, it possibly also braces the chassis legs as well. Have a look at the rear crash bar to see the difference, this is a life saving device and is built like a s**t house, it is designed to protect the fuel tank in the event of a rear end impact

-

fully agree, from memory i think they are about £45, is it worth chancing the engine for 45 quid ?

-

yes yes your right lets make fun of some very young and very scared children who took half an hour to die in a gas chamber, your from Merseyside i see, would you find it offensive if i trivialising young kids "off'ed" at Hillsborough, i would suggest this thread has run its course

-

definately with you on this Chris and i have a solution................. move to Germany when i was working there some years back there was a bad pile up near Duesseldorf involving fatalities, the German emergency services had the autobahn open within an hour, once they had soughted the scene they seemed to take pride in not messing people about and getting the traffic moving, i liked Germany alot, i liked the efficiency, am i normal

-

HELP! How to use MANU mode with a Greddy plenum ?!??!?

paul mac replied to Jamesy's topic in mkiv Technical

yes yes yes pics please when its done and thanks for the heads up i never realised this was the case ditching all the stock throttle -

i'll settle for the 4th most senior member at 11th May 2001 cost £10k and about £25k since , my car is an import and spent only 3 years in Tokyo before arriving in the UK in 1996 (owned by a lady doctor !) so was a very early import

-

what a great thread Dan, this knackered shoulder of yours is really paying dividends for the forum mate

-

yep saw the Alcon stuff on your brake thread, they look very sexy calipers and the cast in bridge looks excellent (mine are bolted in) these should make these calipers uber rigid, i really must look into how they actually machine the piston bores on these monoblock jobbies, when i looked at mine i thought how the $*%# do they do that

-

Scott speaks a lot of sense here, if you wish to keep the stock box stick to around 500 ish hp, you dont have to listen to all the willy waving you need a massive turbo brigade, for an auto a T61 or GT35 size is perfect, on this size of turbo you really dont even need to bother about DBB either. If you think 500 ponies isn't much think about the cars on the road pushing that kind of power, believe me it is embarrassingly easy to beat 99% of cars on the road and quite a big percentage of bikes as well. To stick a tubular manifold on anything under 600hp is IMHO throwing your money down the drain you will increase lag, put more heat into the engine bay and run the risk of cracking, Wez runs 600hp and Dan runs 570hp both on cast manifolds and with the benefit of superior spool up, both are derivatives of what Treadstone performance sell for about £350 shipped (i have one in the garage waiting to fit ) 550's will run 500 hp mine has run successfully for the last 4 years with them at 1.4 bar boost 510hp. The one essential i would advise anyone auto to get is a high stall torque converter, going from lagless stock twins to a single did dissapoint me a bit at first as there is the inevitable lag increase, a 3200 rpm hi-stall absolutely transformed the car. Do your research before you splash the cash, i blew 1k on a tubular manifold when i could have spent £300 on a cast, £700 saved could have bought my hi-stall, you live and learn

-

Hi Dan This is a blast from the past , bracket material was T6 ally, i didn't work out any stuctural loadings i just used the tried and tested battleship engineering principle and made them BIG, are you making your own brackets ? as i have some tips that could save you time. The front face of the pistons is steel and looking through my old pics found one that backs this up, whats on the inside of the caliper is a mystery to me as the front face that contacts the pad may be attached to something else undernieth. As for weights i have seen your thread but i dont have anything exact, i will weigh it all the next time they come off (shame as its all been off recently for my suspension rebuild), from memory there wasn't much in the fronts, lighter by about half a kilo i think but the rears were considerably lighter due to the lack of handbrake gubbins

-

pm Jamie P, he went through a phase of destroying diffs on a weekly basis , i am sure he will know all the permatations

-

anything as long as it has peak and hold, i find this a very usefull feature for checking all's well in the land of boost

-

Inferno's Supra: Restored & Built From The Ground Up

paul mac replied to Inferno's topic in mkiv Supra Projects

Glad it worked out mate and the feelings mutual as i'm a HUGE fan of your build -

Inferno's Supra: Restored & Built From The Ground Up

paul mac replied to Inferno's topic in mkiv Supra Projects

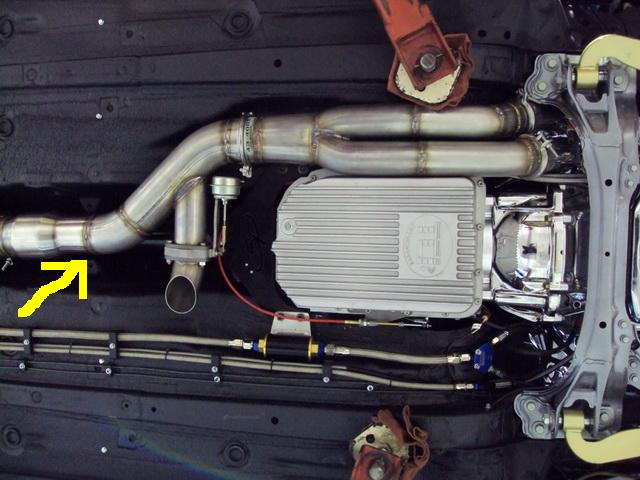

slight critism, looking at the pic of the exhaust cutout to me it doesn't look in the best position, i would have gone for leading it straight off the second bend as marked by the (very crude) arrow to keep the flow as straight as possible, the way you have it is going to reduce back pressure in the exhaust but force the gas flow to make a very abrupt turn as its already changing direction off the first bend, keep the pics coming as its an amazing build -

i have seen those particular pics Chris (i seem to have studied every dual plenum picture i could find ) dont suppose you have any pics of it split do you

-

yes Jay there is, these guys are making me the cone http://www.jasperintegration.com/distribution-plenum.html this is the upper part on mine and would still really be counted as part of the intercooler pipework, check out her for more inspiration http://www.bufkinengineering.com/intake%20manifolds.htm slightly off topic but one thing that has interested me with all the Audi pictures is the amount of trouble these guys took to get an isolated cold air supply to the turbo, i know people have advocated this for years but i am finally inspired to sought my K & N

-

Swapped the pillar drill for MDF, wood glue and fibre glass resin and made up a former for the lower plenum, for anyone who didn't see my brake upgrade i like to make wooden blanks as test pieces and these prove invaluable in helping identify any issues, unlike the brake caliper mounts this plenum former will be used to shape the aluminium. Got the gaskets cut at the local water jet facility http://www.k-cut.co.uk/, these are the adaptor plate to head gasket and the throttle body to adaptor gaskets, O rings would have been cool but i try and minimise any machining operations as i either pay a fortune or wait weeks while someone does it as a foreigner . The water jet cut is spot on and allows accuracy way beyond hand cut gaskets, it will cut anything (they had ceramic tiles on the machine when i was there) you will need someone to do the CAD drawings for you though. The gasket material is Fluolion white 1mm http://www.jameswalker.biz/jwco/products/fluolion_integra_white_and_blue.html i picked this as it handles up to 260 C, has excellent chemical resistance, compress's well with the low torque of the intake studs and the icing on the cake has excellent thermal insulation properties so between the 2 x 1mm layers should keep a bit of heat off, if anyone wants the CAD drawing for the cylinder head gasket for a phenolic type gasket let me know (i may make one of these at a later date)

-

not a TS bonnet more of a PM bonnet but when i went a bit mad with the depth of the vents this is how i soughted it, carbon fibre epoxied in

-

the baffles should be removed when welding the new fittings in as it uses a silicone type sealant which would melt with the heat Dear Mr Graham Bell quotes a 3-4% power increase at 10-12in vac, to my mind yes an engine will run without but the efficiency gains are to big to ignore

-

out of interest A.Graham-Bells book forced induction tuning has a good section on this, he quotes to not exceed 10-12 in vacuum for a street engine and also reckons Moroso vacuum pumps are pretty good http://www.moroso.com/catalog/categorydisplay.asp?catcode=17200

-

Sooooo, I got a couple of questions for those in the know: 1. Am I correct in assumig that if I reduce the size of the port on the manifold where I take the vacuum source, that is a good way of reducing the overall "pull" I'm applying to the crankcase? yes this would work fine, i would copy the stock size which from memory is quite small on the pcv non return 2. Is there any baffle issue I have to concern myself with in the cam covers (like they've been de-baffled or something - sure I read something about the somewhere)? not sure what you mean here, the stock cam covers have baffles in which to my mind would be foolish to remove as they are not a restriction to air flow and Mr T put them there for a good reason 3. Is the stock system (intake cam cover side) literally a link from the cover to the manifold with a check valve? There's nothing else I need to consider? yes it is just a link with a check/non return valve, it is taken off a central location in the plenum, this may be so as not to "upset" any one cylinder or it may be just a packaging solution, i'm really not sure on this, however someone stuck it there for a reason so you wouldn't go far wrong if you followed this